HOW IS YOUR METAL ROOF MANUFACTURED

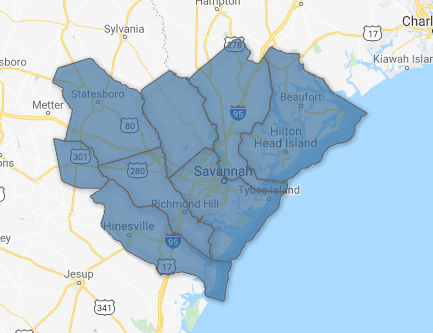

The majority of metal roofs are made of stone coated or painted steel that is purchased in pieces of tiles. Metal covers a lot of ground: there are numerous types of metal available for roofing, and their properties differ. According to South Shore Roofing, the best general contractor in Savannah, GA, manufacturing ways are always determined depending on what kind of metal is used.

Ways of manufacturing metal roof

– Manufacture of the standing seam metal

Various types of metal used for metal roofing include zinc, copper, steel, aluminum and stainless steel. Most popular and widely used are aluminum and galvanized steel.

The first step is the dipping process of the metal coil, for instance, a galvanization process. In this step, the coil has to be put into a boiling blend of zinc and aluminum or galvanic and molten zinc. This process allows the creation of a thin layer around the coil that makes it highly prone to corrosion. However, certain types of metal such as aluminum don’t need to go through the dipping procedure.

The manufacturers then put metal into a machine that generates a thick metal coil which is, in the end, a massive metal roofing panel. The coil has to go through a roll former which creates various bends and curves using a hot furnace with ammonia gasses and cooling pipes in a special chamber where the metal is made softer.

Hereupon, drying and polishing procedures prepare the coil for painting. A unique painting machine first applies a dye with reflective properties on both sides and sends the coil to a special baking ventricle that uses extremely high temperatures to ensure the primer is applied evenly and correctly. The coil goes through another cycle for the main color which has to be implemented in two layers.

The entire manufacturing process is supervised by a computer through a smart control unit that allows automatization of the process. It is extremely precise and accurate and therefore speeds up the entire production.

Here is the end of the first part of manufacturing. The coils travel to different private metal roofing producers and are split and shaped according to their goals and standards. Coils can also be sold to various shops or directly to contractors.

In conclusion, standing seam metal roofs mostly derive from the manufacturers in your area. The difference is mainly in price and warranties that the manufacturer decides to include. It is not the metal manufacturer that determines the quality of your metal roof but your contractor.

Roofing accessories

Even though it doesn’t seem like that, metal panels are just a part of your metal roofing system. Roofing system calls for several different metal roof accessories to function well. Things like drip edge, ridge cap and flashing provide security for your roof. These accessories require precise and accurate processing. Particularly important are the flashings which are made in a sheet metal shop and on sheet metal break ( a particular machine that guarantees precision). To cut strips of metal for flashing producers use automated shear.

– Stone Coating:

Another technique is a stone coating of the panels. It includes coating the metal with stone granules and securing it with the acrylic film. Homeowners who prefer the traditional look of the roof prefer this type of metal roofing.

Different methods and final products:

The ending product is shaped by the metal roofing technology that was used. Here is a quick overview of those:

– Cool Coating:

More and more homeowners and business owners aim at adding a green factor to their properties. The cool layer does exactly that. Coating a metal roofing with a cool layer ensures reflectivity and contributes to the energy efficiency of your home or office.

– Standing Seam Roof:

To form a standing seam roof metal panels have to be connected to raised seams in a vertical position. This construction is more stable in comparison to the traditional one and provides a property with better insulation due to the flexibility of the roof. Standing seam roofs are adored for their attractive appearance as well for the many benefits they offer. Even though they are not entirely new invention, their popularity has grown significantly.

Style of your roof:

The misconception that roofing systems are neglected in an overall exterior design is wrong. The industry follows trends and innovative style and tries to pair it with efficiency and functionality. Metal roofs have been ignored for too long in residential roofing because they were used only on commercial buildings. Luckily, the situation is changing, and today they represent a sophisticated and elegant improvement of your aesthetics.

You don’t have to choose just among steel and aluminum; there are many exotic metals out there that can be a unique fit for your home. Some os those are titanium, rolled zinc, copper, and terne-coated steel. Metal roofing style isn’t limited to just shingles, but you can also pick shakes, tiles, panels, and slate.

Metal roofs are today more than ever seen as an eco-friendly, sustainable and durable roofing solution. The metal roofing industry sets new quality standards every day and pushes contractors to do an even better job installing energy efficient metal roofs. New colors and style allow homeowners to combine green factor of metal with their unique personal taste.